Phone:

(678) 951-0626

Physical address:

4575 Webb Bridge Rd.

Suite #4345

Alpharetta, Georgia 30023

In the Logistics industry, spoilage can be a significant concern, especially when it comes to transporting perishable goods. Whether you’re dealing with food products, pharmaceuticals, or other temperature-sensitive items, minimizing spoilage is essential for maintaining product quality and reducing financial losses. This blog post will provide you with five practical logistical tips to minimize spoilage at the gate which will help ensure the integrity of your cargo from start to finish. So, let’s dive in and explore these beneficial tips that can help you optimize your Logistics operations.

Efficient loading and unloading processes are vital to minimize the time perishable goods spend at the gate. This starts with proper planning and coordination to ensure that the necessary resources, such as reefer trucks, are available and ready for timely loading and unloading. Additionally, consider implementing advanced technologies like RFID (Radio-Frequency Identification) tags or barcode scanners to streamline inventory management and reduce human error. A Logistics Gate Automation system such as TEKControl, can help schedule trucks, visitors, and vendors ahead to accomplish proper planning and coordination.

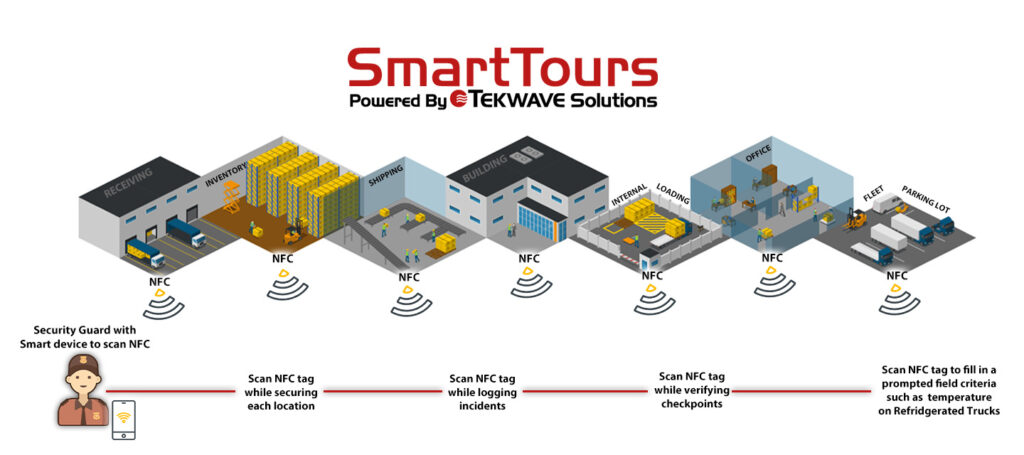

Maintaining the right temperature during transportation is necessary for preventing spoilage. Equip your reefer trucks with advanced temperature monitoring systems such as Sensitech. Another cost-effective solution is to place NFC Tags nearby the trailer waiting location, with a location prompt that generates on a smart device for a guard to input temperature checks with ability to program temperature range, these solutions provide real-time alerts and ensure strict temperature control. These systems can help you identify temperature deviations immediately and take corrective actions before spoilage occurs. Regularly calibrate and maintain these systems to ensure accurate readings throughout the transportation process.

Your Logistics team plays a key role in minimizing spoilage at the gate. Invest in comprehensive training programs that educate your personnel about best practices for handling perishable goods. IATA offers a course on Perishable Cargo Transportation. Teach them how to properly load, secure, and monitor temperature-sensitive cargo to global standards. Ensure they understand the importance of following strict protocols and how their actions impact the overall quality and integrity of the goods being transported.

Choosing the right packaging and securement methods is necessary in preventing spoilage. Use insulated containers or pallets designed specifically for perishable goods to maintain the desired temperature throughout transit. Implement effective blocking and bracing techniques to prevent shifting or damage during transportation. By selecting the appropriate packaging materials and securement methods, you can significantly reduce the risk of spoilage at the gate. Finding the right packaging or pallets for your business is important, new advancements in the transportation pallets, IoT-EnabledPallets for Tracking Perishable Goods from Pallet Alliance.

Develop Strong Supplier Relationships: Maintaining strong relationships with your suppliers is key to minimizing spoilage. Collaborate closely with them to establish clear communication channels and ensure they understand your specific requirements for transporting perishable goods. Share relevant data, such as temperature thresholds, handling instructions, and delivery schedules, to ensure a seamless transfer of goods. Regularly evaluate supplier performance to identify areas for improvement and address any issues promptly. Need help identifying those areas for improvement? What if I told you, it’s as easy as checking someone in at the gate? Developing a strong supplier relationship for security solutions is a necessary part of a streamlined process.

Minimizing spoilage at the gate is crucial for any Logistics operation dealing with perishable goods. By implementing these five Logistical tips, including optimizing loading and unloading processes, effective temperature monitoring, personnel training, proper packaging and securement, and strong supplier relationships, you can significantly reduce the risk of spoilage and ensure the quality and freshness of your cargo. Remember, a well-executed Logistical strategy combined with the use of reefer trucks and advanced monitoring technologies such as those offered by Tekwave Solutions, will go a long way in safeguarding your perishable goods throughout the transportation process.